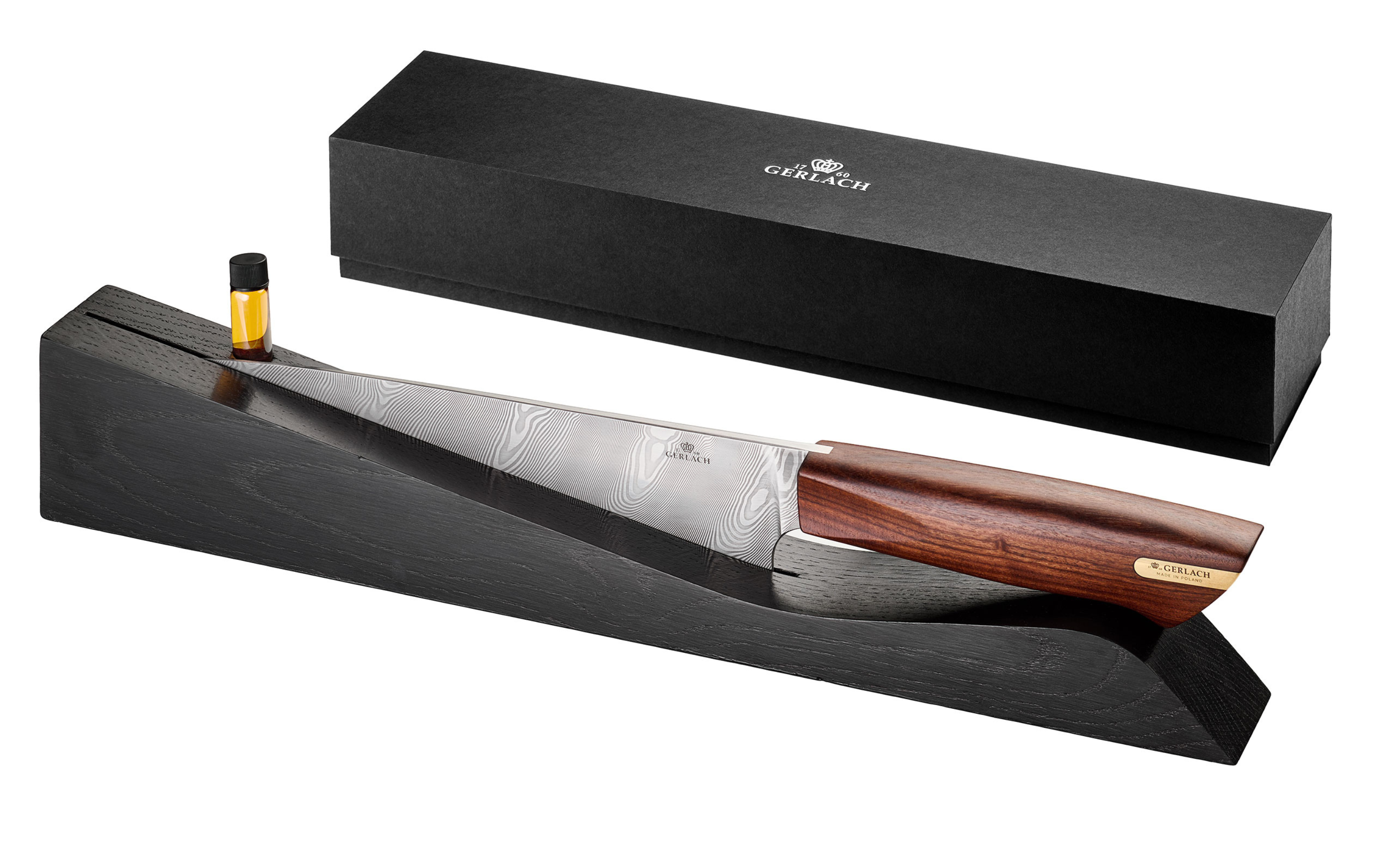

Renowned Damascus steel is an extraordinary blend of various steel types, resulting in unique patterns on the knife blade. We utilized metal welding technology to create a true, functional work of art. Discover the Damascus steel chef's knife N46-DS, which will impress you not only with its sharpness.

What is Damascus steel?

The name originates from the city of Damascus in Syria. It was in that region where the legendary medieval steel was produced, used for making weapons among other things. However, the historical method of production disappeared around the 17th century. This steel was known not only for its superior quality compared to other types of steel from that era but also for the unique patterns on the blade.

Today, the term is typically used to refer to steel that, after being etched in acid, reveals unique patterns on the blade. These patterns are created by welding different types of steel, which react differently to the acid due to their specific compositions. The number of layers can reach several hundred—each visible stripe represents another layer.

The N46-DS knife – a combination of Austrian stainless steel and Nitro B steel

The blade of the N46-DS knife is crafted from a combination of two stainless steels with a hardness of around 60-61 HRC. Austrian N690 stainless steel, also used in other knives from this line, forms part of the blade. Nitro B is responsible for the darker stripes visible on the blade—it has lower nickel and chromium content, making it etch faster. Both steel types share similar properties, allowing for the creation of a unique yet highly functional blade.

How was the pattern on the N46-DS knife created?

The pattern on the N46-DS knife blades was created through the process of welding and then twisting a pre-prepared metal rod. This process is carried out at extremely high temperatures, close to the point of steel combustion. The material is then flattened to the desired thickness, and it is from this that the unique N46-DS knife blades are made. It’s a complex process that demonstrates the highest skills of metallurgists and blacksmiths, ensuring a unique pattern on each knife.

The N46-DS chef's knife – more than just Damascus steel

The N46-DS chef's knife is not only made of high-quality Damascus steel but also features carefully selected materials and a design inspired by the NK-46 knife from the 1980s. The handle is crafted from durable rosewood, known for its rich color and grain, as well as its high hardness and natural oil content. This makes it an excellent choice for kitchen work.

The ergonomic shape of the handle allows for a comfortable grip and a secure hold, ensuring exceptional precision and comfort while cutting. This makes working with the knife for extended periods a true pleasure. The blade shape is designed to be versatile, making the knife suitable for slicing and chopping a variety of products, such as meats, vegetables, and cheeses.

The bolster and pin in the handle are made of copper. They add a unique character to the tool, perfectly complementing the tone of the handle. The pin is engraved with a special serial number, highlighting the collectible nature of this unique knife.

The N46 knife line – an extraordinary history forged in steel

In 1823, Samuel Gerlach opened his knife-making workshop in Warsaw. To honor this date 200 years later, we decided to create a unique line of products characterized by exceptional quality, handcrafted production, and carefully selected materials. This collection includes three chef's knives: the N46-K with a handle inspired by the brand's historic design, the N46-D featuring a modern and ergonomic handle, and the N46-DS, made from unique Damascus steel. These are more than just knives—they are exceptional, handcrafted tools made in Poland, true functional works of art.